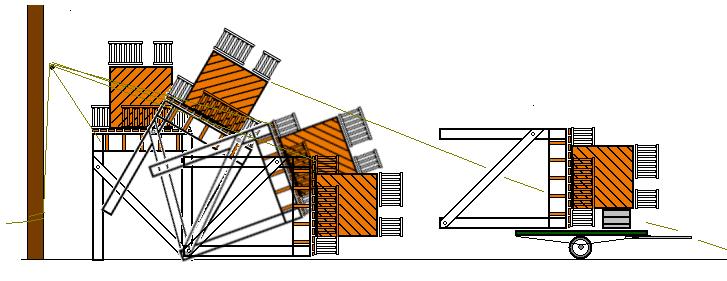

I think it was in 1997 that Pat Wisniewski came to visit and helped me

build this huge climbing structure in the back yard. I wanted something

so high that it

would be worth the effort to climb up to the top and view the world

around.. It was never really finished as some of the railings needed

tops. Ironically, the

railings were the only parts damaged when I recently took the climbing

structure down with the idea of reinstalling it in the back yard of a

friend of our neighbors

Sue and Sheila. I had a plan how to take it down and it was mostly a

workable plan. The structure came down in a very controlled fashion and

there is a movie

you can watch to get an idea of how fast that happened.

The climbing rope got a lot of use. It was an "industrial grade"

climbing rope. It was satisfying to see my boys climbing up that rope.

There was a plan and a concept for taking down the climbing

structure. Here's a movie of the toppling. movie 4,378 kB

The block in tackle came in handy for a couple of operations. One end

is an older wooden block and the other is a newer galvanized block.

They worked together

fine. I used lots of cable and Crosby clamps in this operation as well

as a railroad jack that can lift as much as 20 tones. The block and

tackle, the railroad jack

and most of the steel cable ( 5/16" 7 x 19 plow iron cable) came from

David Doehlert. I also used a lot of 4" x 4" wood cribbing to help lift

and lower the structure.

This one horsepower 12 volt electric winch made life much easier. I

recharged the battery after every operation. However, I never had to

stop at any point

due to the battery having run out of capacity. My battery worked

well. It is pictured a few lines below.

Now I needed an anchor in the right position to pull against. To get

the

club-house portion up the hill I used the Le Sabre as an anchor.

When I tried that for the large base of the structure, I just pulled

the Le Sabre sideways about five feet before I gave up. I may also

place some section of water pipe between the base and the planks being

used as skids, if there is too much drag to move it easily.

Pulling the structure up the hill (see below) required two new

techniques. One, was placing lengths of steel pipe in between the base

of

the structure and the wood planks acting as a skid. Even with the pipes

reducing drag, neither the truck or the big Le Sabre were massive

enough remain stationary as an anchor to pull against. The problem was

solved by running a 5/16" 7x19 steel

cable from a tree in the

back yard to the Oak tree that was halfway up the driveway. Then I

fixed a chain to various points along that

cable depending on where

I needed the winch to be.

Above are pictures showing (left to right) how winch is secured in

middle of cable, winch on Oak in driveway, and pipes used as rollers.

This first picture on the left shows that the structure is really on

the other side of the fence and out of the back yard and now in the

driveway.

The picture on the right shows the two halves of the structure in the

driveway. There is a big pile of our neighbor's mulch still to be moved.

Dawn rented a tilt bed truck and driver. It was perfect. Their winch

was a lot stronger than my winch. We got both halves on the truck.

After prying it into place and attaching flags, we were ready to go the

five miles to it's new home.

I didn't have my camera for the unloading because I left it with Julie

after our truck was rear ended by a jeep.

We started jacking up the club house to get it lined up to be bolted

back through the desk.

The winch allowed me to pull the two halves of the structure tightly

together. I highlighted the cables in red to make the path visible.

Now the climbing structure looked pretty good. It is level

and the clubhouse and the main platform are pulled together tightly.

The old legs had split during moving and needed to be replaced. The 4"x

4" legs were replaced with 4" x 6" legs. The notches were

cut to allow the new legs to fit into place and support the deck under

structure. Notches also support the railing horizontal members.

When the legs were notched, they fit into place replacing the old

splintered legs. The new structure will be more stable.

Finally all three legs have been replaced and the diagonal supports

installed. The stack of cribbing supporting the club house is

replaced with a single support with a "shoe" at the bottom to allow it

to slide as the structure is winched into position to be raised.

The cable got wrapped around the outside of the winch drum in the dark

and jammed it up. It keep working for a while but then

stopped. When I took it apart the second time, the problem was clear.

The internal teeth were worn away.

With the winch now completely broken further work on re-erecting the

climbing structure must wait until a new winch can be bought or

rented.

On October 4th was in Chesterfield, VA again and bought another winch

which was the same model but seemed to be slightly improved.

Unfortunately for others, the improved version was the older

discontinued model. It came without the nice hand held switch but I

still

had that from the old winch.

The new winch has much harder sides to the spool even though it is

obviously the same design as the old winch. My theory which is only

wild speculation is that this better winch was being obsoleted because

the new version was cheaper to make. I am happy to have a winch

as a result of doing this project.

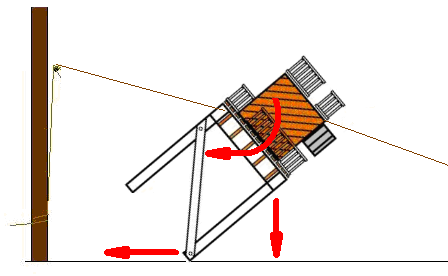

The winch by itself was not able to lift the weight of the

climbing structure. However by using a block and tackle we could

multiple the

power of the winch nearly threefold. The drawback was that we didn't

have room or enough cable to set the block and tackle up to

do it all in one effort. It is really satisfying to be able to

put the block and tackle to good use after all these years. Now with

the winch

I have a new capability.

The first task was to turn the entire structure around. It was harder

than we expected because it was so top heavy with the playhouse

already in place. This was where the winch had failed the month before.

We jacked it level and then had to keep shifting the pile

of cribbing as we pulled it around by the climbing rope bar in the

foreground.

The other thing that I brought was a very old block and tackle that

David Doehlert had given me years ago. The two sets of pulleys

were from different generations, one mostly wooden with still shafts

and wheels and reinforcing and the other all steel. They worked

well together and they allowed the winch to lift the structure from

almost level pulling from what was the highest point at that moment.

I ran into some trouble with what were allegedly 3/8" Campbel cable

clamps. I think these were inferior imitations and I will have pictures

to show the problems shortly. Anyway, I had to stop at 4:00 on Sunday

with the structure pretty much at the point shown in the photos

above and get new clamps, this time from Wall-Mart. The first set were

from a local hardware store chain. With the ratio of about 3:1

I could only bull the cable about 8 feet before the blocks were

together and I had to secure the load and shorten the cable

coming from

the structure.

At the very end when the structure was near the balance point, I took

the block and tackle out and had Dawn on the winch and I

went through a fence to a huge tree on the other side from the winch

and with a heavy cable that went around the tree three times,

I was able to start lowering the entire structure as soon as gravity

was working in our favor. I remember it being at one foot, then at

six inches then at 2 inches and then it was finally on the

ground. The structure was officially re-erected at 8:02 pm on

Sunday

evening October 5th.